Characterization of Fly Ash from Coal-fired Steam Power Plant Tarahan, Lampung, and Its Potential as a Soil Amendment

Main Article Content

Adiksa Insan Mutaqin

Mochammad Chaerul

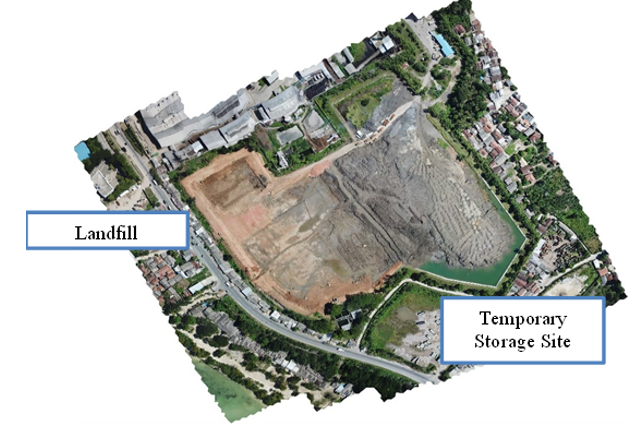

Background: Fly ash, a byproduct of coal combustion in steam power plants, has significant potential for utilization, particularly as a soil amendment. However, in Indonesia, including at the Tarahan coal-fired steam power plant (PLTU Tarahan), most fly ash remains underutilized and is primarily disposed of in landfills.

Aims: This study aimed to analyze the characteristics of fly ash produced at PLTU Tarahan and evaluate its potential for recycling through three utilization pathways: biosilica production, application as a soil-stabilizing agent, and incorporation into compost mixtures.

Methods: Samples were collected from three distinct locations and analyzed at a certified laboratory using standardized procedures. The resulting data were subsequently compared with values reported in existing literature and interpreted using a descriptive analytical approach.

Result: Characterization results indicated that the fly ash belongs to Class F, with high silica (SiO₂) content and low calcium oxide (CaO), making it pozzolanic but non-cementitious. Each reuse pathway was assessed in terms of technical compatibility, infrastructure readiness, pretreatment requirements, market potential, and environmental risk mitigation. The findings showed that biosilica production offers high added value but requires advanced chemical extraction technology. Soil stabilization using fly ash and lime is technically feasible for internal infrastructure and land reclamation projects, offering immediate benefits with minimal pretreatment. When mixed with organic materials such as press mud or combined with garbage enzyme, fly ash also enhances compost maturity, nutrient content, and enzymatic activity. Based on these results, a phased implementation strategy is recommended, beginning with applications that are low-risk and compatible with existing infrastructure. These findings contribute to the development of more adaptive and sustainable fly ash management strategies within coal-fired power plants. To support practical implementation, further laboratory- and field-scale studies are needed to validate long-term performance. Additionally, future research should incorporate multicriteria decision-making approaches, such as the Analytic Network Process (ANP), to comprehensively evaluate technical, environmental, social, and economic factors in selecting the most appropriate utilization pathway.

Andavan, S., & Pagadala, V. K. (2020). A study on soil stabilization by addition of fly ash and lime. Materials Today: Proceedings, 22, 1125–1129. https://doi.org/10.1016/j.matpr.2019.11.323

ASTM International. (2022). Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete (ASTM C618–22). https://www.astm.org/c0618-22.html

Bogacz, A., Kasowska, D., Telega, P., & Dradrach, A. (2024). Influence of Fly Ash on Soil Properties and Vegetation of Fresh Coniferous Forest during Long-Term Observation. Forests, 15(4). https://doi.org/10.3390/f15040593

Chao, X., Zhang, T. an, Lv, G., Zhao, Q., Cheng, F., & Guo, Y. (2023). Sustainable application of coal fly ash: One-step hydrothermal cleaner production of silicon-potassium mineral fertilizer synergistic alumina extraction. Journal of Cleaner Production, 426. https://doi.org/10.1016/j.jclepro.2023.139110

Ekwenna, E. B., Wang, Y., & Roskilly, A. (2023). The production of bio-silica from agro-industrial wastes leached and anaerobically digested rice straws. Bioresource Technology Reports, 22. https://doi.org/10.1016/j.biteb.2023.101452

Febriana, S., Priyadi., & Taisa, R. (2021). The effect of coal fly ash and manure applications as an ameliorant material for the growth of water spinach plant (ipomea reptans poir.). Journal of Agrotek Tropika, 09(01), 161-169.

Gollakota, A. R. K., Volli, V., & Shu, C. M. (2019). Progressive utilisation prospects of coal fly ash: A review. In Science of the Total Environment (Vol. 672, pp. 951–989). Elsevier B.V. https://doi.org/10.1016/j.scitotenv.2019.03.337

Hanum, F. F., Pramudya, Y., Chusna, F. M. A., Desfitri, E. R., Hapsauqi, I., & Amrillah, N. A. Z. (2023). Analysis of Coal Fly Ashes from Different Combustion Processes for The Agricultural Utilization. Journal of Applied Agricultural Science and Technology, 7(2), 73–81. https://doi.org/10.55043/jaast.v7i2.79

Hossain, S. S., Bae, C. J., & Roy, P. K. (2022). Recent progress of wastes derived nano-silica: Synthesis, properties, and applications. In Journal of Cleaner Production (Vol. 377). Elsevier Ltd. https://doi.org/10.1016/j.jclepro.2022.134418

Indiramma, P., Sudharani, C., & Needhidasan, S. (2020). Utilization of fly ash and lime to stabilize the expansive soil and to sustain pollution free environment - An experimental study. Materials Today: Proceedings, 22, 694–700. https://doi.org/10.1016/j.matpr.2019.09.147

Johnson Jeyaraj, N., & Sankararajan, V. (2024). Study on the characterization of fly ash and physicochemical properties of soil, water for the potential sustainable agriculture use - A farmer’s perspectives. International Review of Applied Sciences and Engineering, 15(1), 95–106. https://doi.org/10.1556/1848.2023.00661

Karwal, M., & Kaushik, A. (2020). Co-composting and vermicomposting of coal fly-ash with press mud: Changes in nutrients, micro-nutrients and enzyme activities. Environmental Technology and Innovation, 18. https://doi.org/10.1016/j.eti.2020.100708

Kementerian Pertanian. (2020, June 29). Teknologi pupuk biosilika dari sekam padi. https://pustaka.setjen.pertanian.go.id/index-berita/teknologi-pupuk-biosilika-dari-sekam-padi

Kumar, T., Mishra, S., Naz, S., Pandey, C., & Ali, M. (2024). Optimizing Soil and Crop Productivity Using Coal Fly Ash: A Study from Chhattisgarh, India. GIS Science Journal, 11(8). https://www.researchgate.net/publication/383650703

Liang, G., Li, Y., Yang, C., Zi, C., Zhang, Y., Hu, X., & Zhao, W. (2020). Production of biosilica nanoparticles from biomass power plant fly ash. Waste Management, 105, 8–17. https://doi.org/10.1016/j.wasman.2020.01.033

Liu, H., Xiao, Y., & Jiang, X. (2022). Green Conversion of Coal Fly Ash into Soil Conditioner: Technological Principle and Process Development. Minerals, 12(3). https://doi.org/10.3390/min12030276

Mandpe, A., Yadav, N., Paliya, S., Tyagi, L., Ram Yadav, B., Singh, L., Kumar, S., & Kumar, R. (2021). Exploring the synergic effect of fly ash and garbage enzymes on biotransformation of organic wastes in in-vessel composting system. Bioresource Technology, 322. https://doi.org/10.1016/j.biortech.2020.124557

Mathapati, M., Amate, K., Prasad, C. D., Jayavardhana, M. L., & Raju, T. H. (2021). A review on fly ash utilization. Materials Today: Proceedings, 50, 1535–1540. https://doi.org/10.1016/j.matpr.2021.09.106

Ou, Y., Ma, S., Zhou, X., Wang, X., Shi, J., & Zhang, Y. (2020). The effect of a fly ash-based soil conditioner on corn and wheat yield and risk analysis of heavy metal contamination. Sustainability (Switzerland), 12(18), 1–16. https://doi.org/10.3390/su12187281

Pasalari, H., Moosavi, A., Kermani, M., Sharifi, R., & Farzadkia, M. (2024). A systematic review on garbage enzymes and their applications in environmental processes. In Ecotoxicology and Environmental Safety (Vol. 277). Academic Press. https://doi.org/10.1016/j.ecoenv.2024.116369

Poblete, R., Cortes, E., & Munizaga-Plaza, J. A. (2022). Carbon dioxide emission control of a vermicompost process using fly ash. Science of the Total Environment, 803. https://doi.org/10.1016/j.scitotenv.2021.150069

Peraturan Menteri Lingkungan Hidup Dan Kehutanan Nomor 10 Tahun 2020 tentang Tata Cara Uji Karakteristik dan Penetapan Status Limbah Bahan Berbahaya dan Beracun. (2020). https://peraturan.bpk.go.id/Details/163482/permen-lhk-no-10-tahun-2020

Peraturan Pemerintah Republik Indonesia Nomor 22 Tahun 2021 tentang Penyelenggaraan Perlindungan dan Pengelolaan Lingkungan Hidup. (2021). https://peraturan.bpk.go.id/Details/161852/pp-no-22-tahun-2021

PT PLN Nusantara Power. (2025, March 14). PLN Nusantara Power optimalkan 1,2 juta ton FABA untuk kesejahteraan dan keberlanjutan masyarakat. https://www.plnnusantarapower.co.id/12-juta-ton-faba-dioptimalkan-pln-nusantara-power-untuk-kesejahteraan-dan-keberlanjutan-masyarakat/

PT PLN Nusantara Power Unit Pembangkitan Tarahan. (2025). Laporan pengelolaan B3, limbah B3 dan non B3 terdaftar triwulan IV tahun 2024.

Rafieizonooz, M., Khankhaje, E., & Rezania, S. (2022). Assessment of environmental and chemical properties of coal ashes including fly ash and bottom ash, and coal ash concrete. Journal of Building Engineering, 49. https://doi.org/10.1016/j.jobe.2022.104040

Santi, L. P., Goenadi, D. H., Kalbuadi, D. N., Sari, I. P., & Sulastri. (2021). Alkaline Pre-Treatment of Coal Fly Ash as Bio-Silica Fertilizer. Journal of Minerals and Materials Characterization and Engineering, 09(02), 180–193. https://doi.org/10.4236/jmmce.2021.92013

Taupedi, S. B., & Ultra, V. U. (2022). Morupule fly ash as amendments in agricultural soil in Central Botswana. Environmental Technology and Innovation, 28. https://doi.org/10.1016/j.eti.2022.102695

Utkarsh, & Jain, P. K. (2024). Enhancing the properties of swelling soils with lime, fly ash, and expanded polystyrene -A review. In Heliyon (Vol. 10, Issue 12). Elsevier Ltd. https://doi.org/10.1016/j.heliyon.2024.e32908

Yadav, V. K., & Fulekar, M. H. (2020). Advances in methods for recovery of ferrous, alumina, and silica nanoparticles from fly ashwaste. Ceramics, 3(3), 384–420. https://doi.org/10.3390/ceramics3030034